As an efficient cooking device in modern kitchens, automatic cooking machines have been designed and…

The Intelligent Central kitchen-The Secret of Catering Revenue

Why do many catering industries, such as hotels, restaurants, and cafes start to build intelligent central kitchens? While you are still satisfied with the performance of the traditional commercial kitchen.

It has restaurant owners who have obtained a commercial central kitchen with low energy consumption, automation, high efficiency, and high profit. You are still hesitant to bill for an intelligent commercial kitchen.

What is the central kitchen?

People in a kitchen operation room complete the procurement, selection, cutting of vegetables, and seasoning. It makes the semi-finished ingredients needed by each branch of the restaurant.

It achieves the standardization of the taste and quality of food materials through unified production standards and transportation methods. Many restaurant brands such as McDonald’s, KFC, and Burger King chains have separate central kitchens.

Why do you need an intelligent central kitchen?

The restaurant owner uses intelligent food production equipment to realize automatic, detectable, standardized, and efficient operations. It is the reason why intelligent central kitchens are favored by many catering and food industries.

To a certain extent, the intelligent central kitchen implements more precise/stringent food material production standards and achieves a perfect effect on food hygiene, quality, and taste.

Especially during the Convid-19 period, epidemic prevention and ban policies/restaurant closures / strict hygiene requirements/labor shortages have prompted many catering industries to turn to intelligent central kitchens that can be automated and standardized cooking.

As predicted by relevant agencies, China’s demand for central kitchen equipment will reach 7,900 units, by 2021, or more than 150 billion RMB.

What does the intelligent central kitchen have?

- Intelligent food-making equipment

Take the intelligent central kitchen that makes potato chips as an example. After the product quality testing equipment eliminates part of the inferior potatoes, the high-quality potatoes are transmitted to the automatic cleaning pool. After cleaning, the automatic potato slicing machine (potato chip thickness and cutting time can be customized by the system). Potato chips enter the air-dried tunnel, escape from the surface moisture, and reach the automatic baking equipment.

Potato chips are baked and seasoned by automatic seasoning spraying equipment. Product quality testing equipment will screen each chip, and eliminate broken, irregular, burnt chips; only good chips will enter the automatic food packaging equipment for packaging.

The selection, cleaning, slicing, baking, and packaging with intelligent food-making equipment can realize the standardization of taste and quality, simplify the production process and save the strict requirements for food hygiene.

Data monitoring equipment

In the intelligent central kitchen, the data monitoring equipment will monitor the whole production process dynamically via the Internet. Eliminate, monitor, adjust, and alarm the product quality, environmental health, and equipment safety. It means that you can rely entirely on real-time data to control the quality of your products and strictly comply with food hygiene standards.

The intelligent central kitchen can avoid uneven food quality and poor food hygiene caused by manual operation. It allows you to provide consumers with visual production processes, security & standardized food, and increase your sense of identity, trust, and purchase needs.

Visualization of the food delivery process

An intelligent central kitchen has two ways of transportation: the food distribution of refrigerated trucks and incubators. Restaurant owners can monitor the temperature, quality, and storage of transported food through the intelligent temperature control system; to ensure the visualization and traceability of food materials from production, distribution, and storage.

Lestov offers intelligent kitchen solutions to under-budget restaurants

6 holes automatic noodle-cooking machines

As for cooking equipment that can automatically cook pasta. It has six pasta filters and can cook six portions of vegetables, noodles, and meat. The multifunctional operation interface automatically defines the temperature, heating time, and power, and the automatic lifting button can control the cooking time of the pasta.

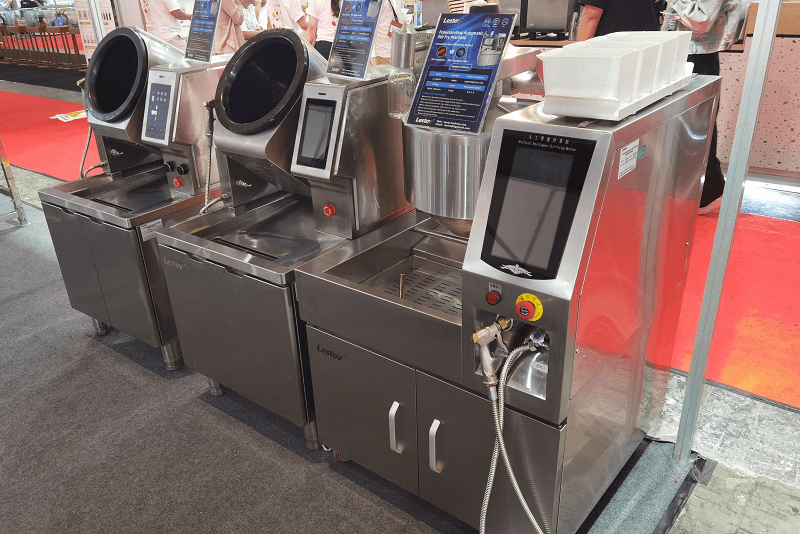

Commercial automatic stir-frying machine

Some restaurants, limited by their budget and a single cooking mode, prefer to choose fully automatic food stir-frying machines. It can realize the automatic stir-fry, seasoning, pouring, cleaning, and other cooking steps. In 100 to 1000 editable menu modes, cooking parameters&steps, and real-time voice prompts can be customized. It realizes the standardization and control of cooking dishes.

What kind of restaurant can build an Intelligent central kitchen?

The central kitchen is more suitable for some food chain brands, the food industry, hotels, and other large commercial kitchens. The central kitchen can match their needs for mass production, food distribution, and automated cooking. Chain restaurants benefit from brand size, multi-type cooking, large demand, and other advantages, more suitable for building intelligent central kitchens.

Who should I contact to build an intelligent central kitchen?

You can contact a kitchen engineer to customize an intelligent central kitchen that meets your needs. They have professional experience in commercial kitchen construction and can obtain high quality, cost-effective, full range of food-making machines from many equipment manufacturers.

Of course, you can also contact commercial cooking equipment manufacturers directly. They can provide you with a full range of equipment, ranging from stir-frying, frying, grilling, cooking, and stewing.

Ez a bejegyzés 0 megjegyzésekkel rendelkezik