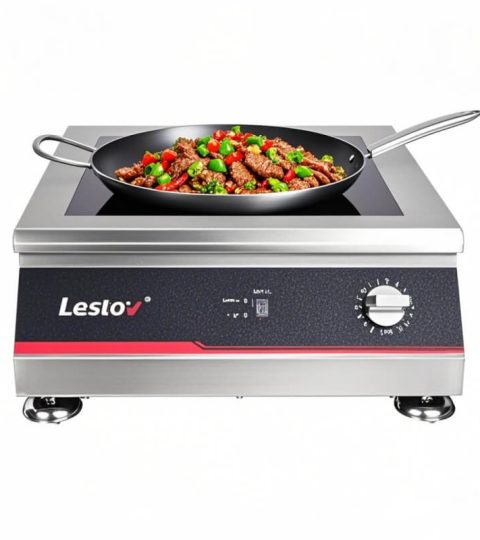

In the catering industry, efficiency and precision are crucial. Commercial induction fryers are gradually becoming…

Simple Guides for Commercial Induction Cooking Equipment

There are 3 types of cooking equipment on the market: gas stoves, electric commercial cooktops, and commercial induction hobs. Here simply speaking the advantages of 3 types of products.

(1) Gas products are common in the market, but many accidents happen, such as gas explosions, fires, air pollution, and other hazards.

(2) Electric heating products always consume high power. To ensure safety, the electric heating tubes should be replaced every 3 months, which will cause huge maintenance costs. Therefore, it is generally not recommended to use high-power electric heating products in large commercial kitchens.

(3) According to market demand, the birth of commercial induction cooktops is regarded as green, environmentally friendly, and cost-effective products.

Here, let’s talk about the key factors considered when buying a commercial induction range cooker.

The voltage of commercial induction cookers

It is decided whether the product can be used for your local kitchen voltage. For example, most of the induction cookers produced in China are 220V / 1 phase electricity, and the high power is 380V / 3 phase electricity, but the 3 phase electricity is limited in the European market.

Firstly, making sure that the local kitchen can use industrial electricity is the first -factor that needs consideration. And combined with the land area of European countries, the high rents generally lead to the limited use of kitchens, which is why some customers require small-size products. These conditions determine whether the product can be used.

Commercial Induction Cooker Features

1) Internal core component

The details of the induction cooker should be analyzed from internal accessories, which determine whether the performance of the product is stable and the service life of the induction cooker. The internal component PCB board looks like the brain of a human, and IGBT is the core accessory on the PCB board.

So the quality of IGBT determines the stability of the entire product. At present, the Infineon IGBT produced in Germany is the industry leader for your reference.

2) Product materials

Including products material and cookware materials, General 304 stainless steel is recommended for the commercial kitchen, there are also 201 materials on the market with a little lower price, but they easily caused food to become black if using the pot with 201 materials, and influence the test and appearance of food.

3)Main cooing method

General products are designed according to the cooking method of different countries, so you need to consider whether this type of product can meet your main cooking method before buying.

4) Product production process

From the product production process, full welded construction greatly increases the appearance of the product and also for consumers to easy cleaning

5 ) Product safety features

This mainly refers to the Internal Build-in protection test system, such as 3 hours without operating automatic shutdown, automatic protection when High/low voltage & Overheating & Overcurrent.

Commercial Induction Cooker Cost

Including product cost and transportation cost, the product cost and related maintenance cost are determined by the quality and materials of the internal parts of the product which is mentioned above.

The transportation cost generally depends on the demand time of the product, When the order is very urgent, the cost of air shipment will be higher. For regular delivery orders, it is recommended to choose sea shipment with low shipping costs.

If you have a better commercial induction cooker purchase experience, welcome to share it with us to exchange some good ideas! Thank you!

Dette innlegget har 0-kommentarer