In the catering industry, efficiency and precision are crucial. Commercial induction fryers are gradually becoming…

Electrical Requirements to Consider for Your Commercial Cooker

Gas cooking generates indoor pollution and other impacts on health and safety. Additionally, the cost of a commercial kitchen hood system is accumulating. As a result, many restaurants and other hotel industries are slowly investing in and adopting commercial induction cookers.

Moreover, many manufacturers are importing induction cookers and complete induction parts from China and offering domestic consumers compatible commercial kitchen equipment, and promoting the induction cooker’s adoption rate.

As an experienced commercial induction hob cooker manufacturer and exporter, I would recommend potential buyers consider electric requirements and methods of wire connections before purchasing induction cookers.

Simple Formula

The formula is -I = P / V. This formula can calculate the maximum amperage in a commercial kitchen after knowing the range of power rating, nominal voltage, and nominal power (“I” represents the “Electric Current” symbol).

Power

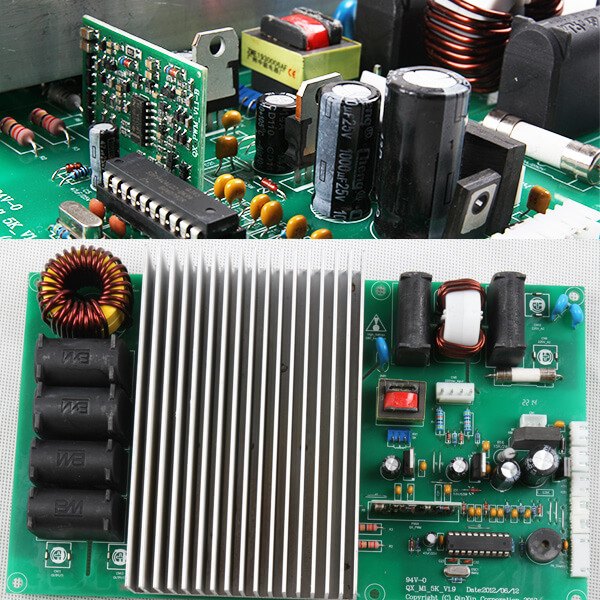

Customers must have essential knowledge of the cookers’ connection input power rating and power configuration between each part.

Chinese commercial induction range cooker manufacturers have realized that “power-sharing” cooking equipment may not be suitable for high-speed commercial kitchens, because, at the peak of the meal, chefs need to diversify the elements of the cooktop.

Taking countertop double burners induction cooktops as an example, because of independent controls, the chef can use 1 or 2 burners as needed, which greatly improves the flexibility and accessibility of the kitchen.

Voltage

Many people asked similar questions on Quora-” can the 220V (50Hz) commercial induction cooker function under 230V or 240V (60Hz)?” My previous purchase experience has proved that they both can function normally.

Although the power supply standards around the world are different, the main power supply voltage will have some wiggle margin, which is called the voltage floating range.

For instance, the Chinese 220V countertop induction stovetop has a nominal voltage range between ±20%, which indicates all induction hob cookers are functional between 176V to 264V. When the (working) voltage exceeds the internal safety protection feature, the commercial induction range cooker will display an error code and stop working.

The signal of AC (alternating current) changes periodically, and the ordinary power frequency is 50 or 60Hz. You can treat the frequency as a reciprocal of time. In 1 second, the IGBT of the commercial induction range cooker will work 100 times. When working at 50Hz, the time is 0.02S (1/50), and when at 60Hz, the time is 0.017S (1/60). So the difference between them is not obvious.

Electric current

Underrated voltage, the current changes parallel with the power. Moreover, the standard current adjustment ranges from ±10%. In a certified commercial induction cooktop, its current and power must match its related requirements.

Requirements of electric in commercial induction range cooker:

Commercial kitchen investors need to be mindful of induction range cookers’ power, current, electric phase, and connection setup.

Customers need to consider the circuit breaker’s size and standard based on induction output. Furthermore, the maximum output capacity cannot exceed connection capacity. It is a crucial process for the customer to enquire about electric requirements from hob manufacturers.

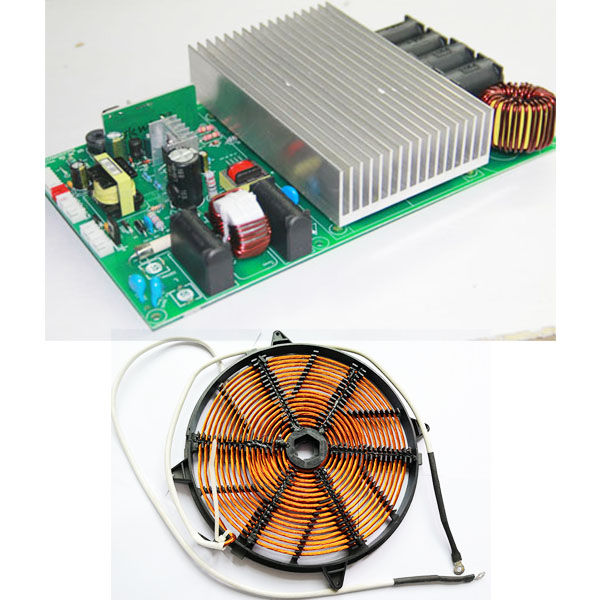

induction wok cookers have a single and 3-phase power supply. Based on different models of commercial induction wok cookers, the cable from the device can have three or four, or five wires.

Some countries allow the neutral wire to be connected to the ground of the commercial induction burner cooker, while some are prohibited. Customers can connect the wire through the junction box according to the domestic code. Please carefully follow the cooker manufacturer’s instruction menu.

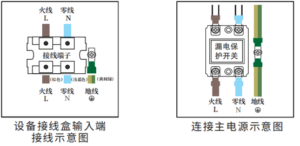

Wire Connection of Countertop Induction Cooker

Countertop induction cooktops made in China commonly use 220V. Moreover, customers need to play the right wiring connection and use safety switches due to high-power output (≥3.5KWw). It is better to install the power connection with a professional electrician.

What do I need to know before installing an induction range cooker?

Please carefully read through the instruction on electric requirements before installation. Now, let us gather 4 tips of Lestov’s nameplate on wire connection:

- Please read the data on the nameplate carefully and confirm the live wire, neutral wire, and ground wire before connecting the power.

- Wire connections must be installed by an electrician. Additionally, the power cable should support the cooker’s current, secure the power cable, tighten the fixing screw and select a reliable ground wire.

- When installing the power supply wires, use a U-shaped pressure piece to compact the cable to prevent accidents caused by looseness.

- Before connecting to the power grid, please make sure the device power passes through an external leakage protection switch with sufficient current capacity.

- The leakage switch can be easily and independently disconnected. Make sure that the ground wire is fully touching the ground, not controlled by the switch.

|

Rated Power Output |

Rated Current |

Power Supply Requirements |

Leakage Switch Requirements |

| 1KW | 4.5A | Single-phase 3 wires: 3×1.5mm² | 32A |

| 2KW | 9.9A | Single-phase 3 wires: 3×2.5mm² | 32A |

| 3.5KW | 15.9A | Single-phase 3 wires: 3×4mm² | 32A |

| 5KW | 22.7A | Single-phase 3 wires: 3×6mm² | 60A |

| 7 | 31.8A | Single-phase 3 wires: 3×10mm² | 60A |

| 8.5 | 38.6A | Single-phase 3 wires: 3×10mm² | 80A |

| 10 | 45.5A | Single-phase 3 wires: 3×16mm² | 80A |

How to install and connect the induction cooker?

Learning all requirements on the nameplate is an essential procedure before connecting. (Reminder: In international trade, tabletop induction hob cookers for export usually do not have a plug.)

3 steps:

- Locate the cable wire behind the cooker

- Connect the live wire (L: brown), neutral wire (N: blue), and ground wire (green and yellow) to their corresponding slots, and be “supervised” by the leakage protection switch.

- Tighten the screw to ensure all cables are fixed in place.

What happens if the wiring is wrong?

- You may hear a sound similar to a balloon explosion. The display of the commercial induction range cooker will turn black and will not work, which will happen at high voltages.

- You can disassemble the commercial induction range cooker and see if the varistor on the motherboard has burned out. The worst result is to repurchase the PCB motherboard.

- The LED display of the commercial induction range cooker will constantly flash failure code 6. Because of the low voltage, the induction range cooker enters a voltage protection program, which is one of the safety features.

- If you readjust the wiring sequence and keep the wiring connection correctly, the induction hob cooker can work.

Konklusion

Compared to the product price and ease of use, usability is a prerequisite. Above all, there is no price for security. Therefore, for those who tend to buy induction cooking equipment from China, electrical induction requirements need your careful inquiry, research, and preparation.

If you have any questions about the electrical requirements or installation process of the induction cooker, you can leave a message under this article or contact the Lestov commercial induction cooker manufacturer directly.

Dette indlæg har 0-kommentarer