In today's fiercely competitive catering industry, an efficient and stable fryer often determines the speed…

Comparison between Commercial Induction Fryers and Commercial Electric Fryers – Lestov Manufacturer

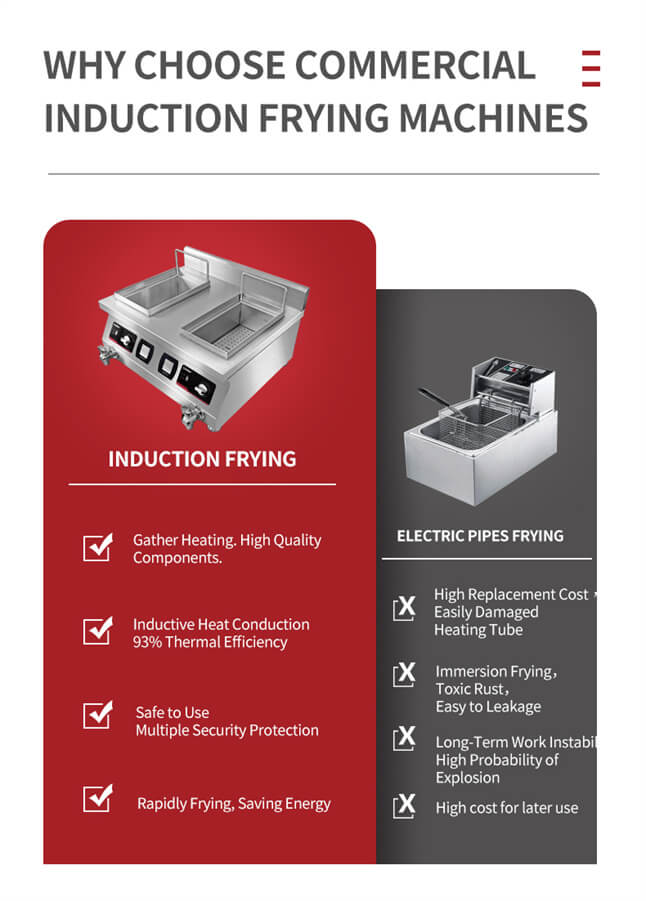

In the modern catering industry, the selection of frying equipment is crucial to improving cooking efficiency, ensuring food safety, and reducing operating costs. Commercial induction fryers and commercial electric fryers are two leading frying equipment types, each with its characteristics and advantages.

This article will compare commercial induction fryers and electric fryers from multiple angles and finally recommend that users choose commercial induction fryers.

I. Characteristics of commercial Induction fryers

1. Working principle

Commercial induction fryers use the principle of induction to generate an alternating magnetic field through an electronic circuit board. When the bottom of an iron pot is placed on the stove, the pot cuts the alternating magnetic field lines and generates an alternating current (eddy current).

The eddy current makes the iron molecules of the pot move irregularly at high speed, and the molecules collide and rub against each other to generate heat energy, thereby heating the food in the pot.

This heating method directly acts on the bottom of the pot, with a thermal efficiency of more than 90%, which is 50%-60% more energy-efficient than traditional electric fryers.

2. Complete functions

Commercial induction fryers can complete a variety of cooking functions, such as frying, stir-frying, boiling, stewing, and braising, and are particularly suitable for occasions where fuel supply and safety conditions are limited.

It is easy to operate, the one-button operation and digital display are simple, and the intelligent computer control technology has the functions of automatic detection of the pot body, overheating and empty burning protection, and overload protection.

3. Green and environmentally friendly

Commercial induction fryers have no combustion exhaust gas emissions, do not consume oxygen, are noiseless and pollution-free, and save energy. Its efficient heating method reduces heat loss, lowers kitchen temperature, and improves the working environment.

4. Safe and reliable

Commercial induction fryers have no open-flame combustion, no exhaust gas emissions, and no combustion leakage, and they avoid potential safety hazards to personnel and the environment. Its power switch has an automatic protection device to reduce the occurrence of accidents.

5. Improve the environment

Commercial induction fryers have no open-flame combustion and no blast device, reduce heat dissipation, improve energy efficiency, reduce noise, and improve the kitchen environment.

6. Reduce supporting equipment

Commercial induction fryers do not need to be equipped with oil pipes, exhaust pipes, etc. when installed. They are ready to use and are light and flexible when moved.

7. Save space

Commercial induction fryers are small in size, high in thermal efficiency, and fast in heating speed, which significantly saves the use area of the site.

8. Accurate temperature control

Commercial induction fryers can accurately control the cooking temperature, which is energy-saving and ensures the deliciousness of the food, which is conducive to the promotion of Chinese food production standards.

II. Features of commercial electric fryers

1. Working principle

Commercial electric fryers use the thermal effect generated by current passing through resistors for heating. The heating tube is cheaper than the induction heating, but its life is also shorter than that of the induction heating.

2. Complete functions

Commercial electric fryers can complete a variety of cooking functions, such as frying, stir-frying, boiling, steaming, stewing, braising, and boiling, and are suitable for various commercial kitchen environments. It is easy to operate, simple to adjust the temperature, and easy to control.

3. Green and environmentally friendly

Commercial electric fryers have no combustion exhaust gas emissions, do not consume oxygen, are noiseless and pollution-free, and save energy. Its efficient heating method reduces heat loss, lowers kitchen temperature, and improves the working environment.

4. Safe and reliable

The commercial electric fryer has no open-flame combustion, no exhaust gas emissions, and no combustion leakage, avoiding potential safety hazards for personnel and the environment. Its power switch has an automatic protection device to reduce the occurrence of accidents.

5. Improve the environment

The commercial electric fryer has no open-flame combustion and no blast device, which reduces heat dissipation, improves energy efficiency, reduces noise, and improves the kitchen environment.

6. Reduce supporting equipment

The commercial electric fryer does not need to be equipped with oil pipes, exhaust pipes, etc. when installed. It is ready to use and light and flexible when moved.

7. Space saving

The commercial electric fryer is small in size, high in thermal efficiency, and fast in heating speed, which significantly saves the site area.

8. Accurate temperature control

The commercial electric fryer can accurately control the cooking temperature, which is energy-saving and ensures the deliciousness of the food, which is conducive to the promotion of Chinese food production standards.

III. Comparison between commercial induction fryers and commercial electric fryers

1. Comparison of core technology principles

(1) Commercial electric fryers (resistance heating type)

- Heating structure: A U-shaped nickel-chromium alloy heating tube is used to directly heat the thermal oil through the thermal effect of electric current

- Heat transfer path: electric energy → thermal energy → metal tube → thermal oil → food

- Temperature control method: bimetallic strip mechanical temperature control (error ±15℃) or PID electronic temperature control (error ±5℃)

- Thermal efficiency: about 60%-65% for traditional models and up to 70% for high-end models

(2) Commercial induction fryers (induction type)

- Heating structure: high-frequency induction coil (frequency 18-25kHz) excites the eddy current effect of the iron pot

- Heat transfer path: electric energy → magnetic field energy → pot body eddy current → direct heating of thermal oil → food

- Temperature control method: IGBT intelligent module + digital PID algorithm (error ±1℃)

- Thermal efficiency: industry-standard 88%-92%; some military-grade products can reach 95%

2. Energy saving and environmental protection

(1) Commercial induction fryer

The thermal efficiency is as high as over 90%, which is 50%-60% more energy-saving than traditional electric fryers. No combustion exhaust gas emission, no noise, no pollution, and energy saving.

(2) Commercial electric fryer

The thermal efficiency is generally 80% -90 %, which is lower than that of induction fryers. Although there is no combustion exhaust gas emission, the power conversion efficiency is low.

3. Safety

(1) Commercial induction fryer

No open flame combustion, no exhaust gas emission, no combustion leakage, avoiding safety hazards to personnel and the environment. Its power switch has an automatic protection device to reduce the occurrence of accidents.

(2) Commercial electric fryer

No open flame combustion, no exhaust gas emission, no combustion leakage, avoiding safety hazards to personnel and the environment. However, the electric heating tube is prone to overheating, which poses specific safety hazards.

4. Convenience of operation

(1) Commercial induction fryer

Easy to operate, one-button operation and digital display are simple, and intelligent computer control technology has automatic detection of pot body, overheating and empty burning protection, and overload protection functions.

(2) Commercial electric fryer

Easy to operate, simple temperature adjustment, and easy to control. However, it is necessary to check the electric heating tube regularly to ensure its regular operation.

5. Cleaning and maintenance

(1) Commercial induction fryer

The heating surface is usually made of smooth glass ceramic material, which is easy to clean and does not produce oil smoke and carbon deposits like electric fryers.

(2) Commercial electric fryer

The electric heating tube is prone to carbon deposits and is difficult to clean. It needs to be disassembled and cleaned regularly, which increases labor costs.

6. Applicable scenarios

(1) Commercial induction fryer

Suitable for modern kitchens that require precise temperature control and energy saving, especially for places where open flames are restricted.

(2) Commercial electric fryer

Suitable for occasions that require fast heating and simple operation, especially for small kitchens and mobile stalls.

-

Friteuse à induction commerciale à double cuve LT-ZAL

Friteuse à induction commerciale à double cuve LT-ZAL -

Friteuse à induction portable à deux paniers pour restaurants LT-TZL-B105

Friteuse à induction portable à deux paniers pour restaurants LT-TZL-B105 -

Single Tank Restaurant Tabletop Induction Deep Fryer with Thermostatic 8L LT-TZL-D135

Single Tank Restaurant Tabletop Induction Deep Fryer with Thermostatic 8L LT-TZL-D135 -

Tabletop Double Tank Restaurant Induction Fish Fryer LT-TZL-S135

Tabletop Double Tank Restaurant Induction Fish Fryer LT-TZL-S135 -

Friteuse à induction robuste à quatre plaques 72L LT-ZAL-D112

Friteuse à induction robuste à quatre plaques 72L LT-ZAL-D112 -

Friteuse commerciale à induction avec roulettes LT-ZLII-E112

Friteuse commerciale à induction avec roulettes LT-ZLII-E112 -

Friteuse commerciale de comptoir à induction à réservoir unique LT-TZL-B135

Friteuse commerciale de comptoir à induction à réservoir unique LT-TZL-B135 -

Friteuse à induction commerciale à double panier 27L LT-ZLII

Friteuse à induction commerciale à double panier 27L LT-ZLII

IV. Comparison of 8 core performance indicators

1. Heating efficiency and production speed

(1) Preheating time

- Electric heating: 20L oil temperature rises to 180℃ in 18-25 minutes

- Induction: only 8-12 minutes under the same conditions (speed increase of 55%+)

(2) Continuous working stability:

- Electroheating has a temperature drop of 5-8℃ after 4 hours of continuous operation

- Induction can maintain a constant temperature of ±1℃ for more than 12 hours

2. Energy consumption and economic comparison (taking the 30L model as an example)

| Parameter | Electric Fryer | Induction Fryer |

| Rated Power | 15kW | 12kW |

| Average Daily Working Hour | 10 Hours | 10 Hours |

| Daily Power Consumption | 150kWh | 108kWh |

| Annual Operating Days | 300 days | 300 days |

| Annual Power Consumption | 45,000kWh | 32,400kWh |

| Electricity Cost(1yuan/kWh) | 45,000 yuan | 32,400 yuan |

| Annual Savings | – | 12,600 yuan |

Note: Actual test data shows that induction equipment can reduce energy consumption costs by 28.6%

3. Oil oxidation control

(1) Oil temperature fluctuation range:

- Electric heating: ±10-15℃ (accelerates oil polymerization reaction)

- Induction: ±1℃ (reduces free radical generation)

(2) Oil change cycle:

Electric heating: 80-120 hours

induction: 150-200 hours (extended by 67%+)

4. Safety protection system

(1) Special protection of induction fryer:

- Non-magnetic pot detection (automatic power off)

- Three-dimensional temperature monitoring (oil temperature, coil temperature, ambient temperature)

- Intelligent oil volume monitoring (anti-dry burning system)

- IP65 waterproof circuit board

5. Space utilization

(1) Equipment volume

The electric heating type needs to reserve 20cm of heat dissipation space

Induction type supports wall installation (0 spacing)

(2) Heat removal requirements

Electroheating type generates 4000-6000BTU/h waste heat

induction type waste heat <800BTU/h (reduces air conditioning load)

6. Maintenance cost analysis

| Maintenance Items | Electric Heating Annual Cost | Induction Heating Annual Cost |

| Heating Tube Replacement | 800-1200 yuan | 0 yuan |

| Thermostat Maintenance | 300-500 yuan | 50-100 yuan |

| Cleaning Labor Cost | 30 hours/year | 30 hours / year |

| Total Cost Different | About 2350 yuan | Saving 58% |

7. Equipment life cycle

(1) Electric heating type

Core component life: heating tube 2-3 years, thermostat 3-5 years

Whole machine scrapping cycle: 5-8 years

(2) induction type

IGBT module life: ≥100,000 hours

Whole machine scrapping cycle: 10-12 years

8. Environmental performance

(1) Carbon emissions (annual):

- Electric heating: 45,000kWh×0.785kg/kWh=35.3 tons

- induction: 32,400kWh×0.785kg/kWh=25.4 tons

- Carbon reduction benefits: 9.9 tons/year (equivalent to planting 540 fir trees)

V. Reasons for recommendation

1. Energy saving and environmental protection

The high thermal efficiency and pollution-free emissions of commercial induction fryers make them the first choice for energy-saving and environmental protection. In long-term use, they can significantly reduce energy consumption and operating costs, meeting the sustainable development requirements of the modern catering industry.

2. Safety

Commercial induction fryers have no open-flame combustion, no exhaust gas emissions, and no combustion leakage, avoiding potential safety hazards to personnel and the environment. The power switch has an automatic protection device to reduce the occurrence of accidents. It is particularly suitable for use in high-rise buildings, basements, and other places where the use of open flames is restricted.

3. Convenience of operation

Commercial induction fryers are easy to operate, with a one-button operation and a simple digital display. Intelligent computer control technology has automatic detection of the pot body, overheating and empty burning protection, and overload protection.

Its fast response characteristics enable chefs to control the cooking process more accurately and improve cooking efficiency and quality.

4. Cleaning and maintenance

The heating surface of commercial induction fryers is usually made of smooth glass ceramic material, which is easy to clean and does not produce oil smoke and carbon deposits like electric fryers. Its maintenance cost is low, and it only needs simple cleaning and inspection regularly to keep it in good working condition.

5. Applicable scenarios

Commercial induction fryers are suitable for modern kitchens that require precise temperature control and energy saving, especially for places where open flames are restricted. It is small in size, high in thermal efficiency, and fast in heating speed, which significantly saves the use area of the site and is suitable for use in various commercial kitchens.

Conclusion

In summary, commercial induction fryers are superior to commercial electric fryers in terms of energy saving, environmental protection, safety, convenience of operation, cleaning, and maintenance.

Although commercial electric fryers may have a price advantage, in the long run, the comprehensive benefits of commercial induction fryers make them a better choice for the modern catering industry.

Therefore, it is recommended that users choose commercial induction fryers to improve kitchen efficiency, ensure food safety, and reduce operating costs.

machine de cuisson automatique machines de cuisson automatiques bbq chip fryer commercial cooking equipment commercial drop in induction cooker commercial food steamer commercial induction cooker commercial induction cooktop friteuse commerciale à induction commercial induction fryer plaque de cuisson commerciale à induction commercial induction soup cooker Cuiseur vapeur à induction commercial commercial induction wok cooker commercial kitchen cookware food steamer hob induction cooker induction cookware INDUCTION FRYER induction grill induction hob iron wok kitchen equipment repair guide restaurangt equipment restaurant equipment stainless steel cookware user's guidance

Cet article comporte 0 commentaires